Cotton and Cotton Trade in the Middle Ages

Ciba Review 64, Basle,February 1948

Cotton in the Ancient World

The Beginnings of the Cotton Industry in Europe

Cotton Growing and Cotton Trade in the Orient during the Middle Ages

Fustian Weaving in South Germany from the Fourteenth to the Sixteenth Century

Schürlitz Weaving in Switzerland

Notes

Home

Cotton in the Ancient World

By H. Wescher

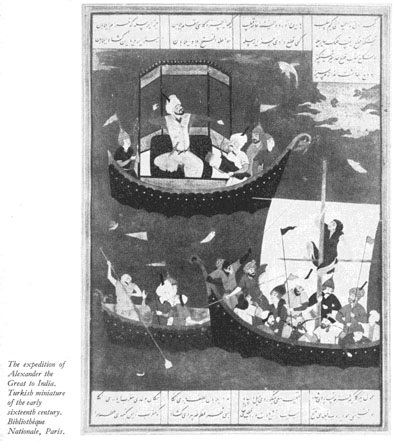

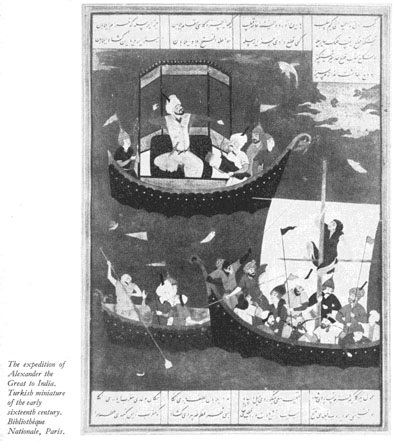

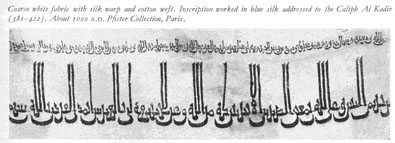

From the earliest times down to the present day cotton has been a factor of undiminishing importance in India. Early Sanskrit writings contain references to the use of cotton; the ancient laws supposed to have been recorded by Manu refer to the sacred cord worn by the Brahmins, stating that it should be threefold and of cotton. This reference is in keeping with another one according to which cotton served as material for the robes of the priests of ancient eastern religions; it was only at a later date that its use was extended by the caliphs to the manufacture of secular clothing. In these early records cotton is referred to as "karpasa", a name which passed from Indian into the Hebrew and Latin literature. It is assumed to be connected with the town of Carpasia in Cyprus which for a long time was an important centre of the cotton trade. One of the oldest reports on the processing of cotton comes from Herodotus (approximately 490-424 a.c.), who wrote: "The Indians have a wild-growing tree which instead of fruit produces a species of wool similar to that of sheep, but of finer and better quality. The Indians make their clothing of this material." A statement made by Ktesias, a contemporary of Herodotus, on the spinning and weaving of this vegetable fibre is confirmed by Varro (first century n.c.) in the following words: "Ktesias states that there are trees in India which bear wool." These somewhat laconic reports are supplemented by the writings of Theophrastus (fourth century B.C.), who gave a vivid description of the plant: "The trees from which the Indians make their clothes have leaves like those of the black mulberry, but the plant as a whole resembles the dogrose. They plant these shrubs in rows in flat ground; when seen from a distance they have the appearance of vines." Aristobulus, who accompanied Alexander the Great (336 to 323 B. C.) to India and who wrote a description of the expedition, refers to a "wool-bearing tree which grows to a height of three or four feet, and from the capsules of which the seeds are taken out in order to secure the fibres which are combed like wool." Nearchos, the admiral of Alexander's fleet, was of the opinion that the "linen" Cloth woven out of this fibre was finer and whiter than any other fabric. The Indians wrapped themselves from head to foot in this material. Nearchos states that they wore a shirt of cotton, reaching half way down the leg, a cloak wrapped round the shoulders, a turban wound round their heads.

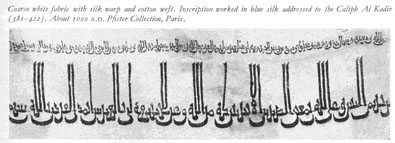

From the earliest times down to the present day cotton has been a factor of undiminishing importance in India. Early Sanskrit writings contain references to the use of cotton; the ancient laws supposed to have been recorded by Manu refer to the sacred cord worn by the Brahmins, stating that it should be threefold and of cotton. This reference is in keeping with another one according to which cotton served as material for the robes of the priests of ancient eastern religions; it was only at a later date that its use was extended by the caliphs to the manufacture of secular clothing. In these early records cotton is referred to as "karpasa", a name which passed from Indian into the Hebrew and Latin literature. It is assumed to be connected with the town of Carpasia in Cyprus which for a long time was an important centre of the cotton trade. One of the oldest reports on the processing of cotton comes from Herodotus (approximately 490-424 a.c.), who wrote: "The Indians have a wild-growing tree which instead of fruit produces a species of wool similar to that of sheep, but of finer and better quality. The Indians make their clothing of this material." A statement made by Ktesias, a contemporary of Herodotus, on the spinning and weaving of this vegetable fibre is confirmed by Varro (first century n.c.) in the following words: "Ktesias states that there are trees in India which bear wool." These somewhat laconic reports are supplemented by the writings of Theophrastus (fourth century B.C.), who gave a vivid description of the plant: "The trees from which the Indians make their clothes have leaves like those of the black mulberry, but the plant as a whole resembles the dogrose. They plant these shrubs in rows in flat ground; when seen from a distance they have the appearance of vines." Aristobulus, who accompanied Alexander the Great (336 to 323 B. C.) to India and who wrote a description of the expedition, refers to a "wool-bearing tree which grows to a height of three or four feet, and from the capsules of which the seeds are taken out in order to secure the fibres which are combed like wool." Nearchos, the admiral of Alexander's fleet, was of the opinion that the "linen" Cloth woven out of this fibre was finer and whiter than any other fabric. The Indians wrapped themselves from head to foot in this material. Nearchos states that they wore a shirt of cotton, reaching half way down the leg, a cloak wrapped round the shoulders, a turban wound round their heads.

Alexander's expedition to India gave to the scholars of the Western world an entirely new opportunity of becoming acquainted with the nature and extent of Indian civilization. The advantage which they took of this opportunity is revealed in geographical writings such as the "Circumnavigation of the Red Sea" (Periplus Maris Erythraei), the author of which is believed to be Arrianus (about A.n. 95-175). It contains a considerable amount of information on the Indian textile arts, mentions Ariaca and Barygaza on the west coast as the most important export centres and Masulipatan and Palarimunda on the east coast as the principal centres of manufacture. Arrianus also states that the finest muslins came from the district of the Ganges delta, and that they were described by the Greeks as "Gangetiki".

Alexander's expedition to India gave to the scholars of the Western world an entirely new opportunity of becoming acquainted with the nature and extent of Indian civilization. The advantage which they took of this opportunity is revealed in geographical writings such as the "Circumnavigation of the Red Sea" (Periplus Maris Erythraei), the author of which is believed to be Arrianus (about A.n. 95-175). It contains a considerable amount of information on the Indian textile arts, mentions Ariaca and Barygaza on the west coast as the most important export centres and Masulipatan and Palarimunda on the east coast as the principal centres of manufacture. Arrianus also states that the finest muslins came from the district of the Ganges delta, and that they were described by the Greeks as "Gangetiki".

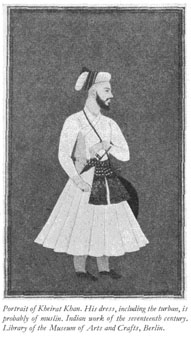

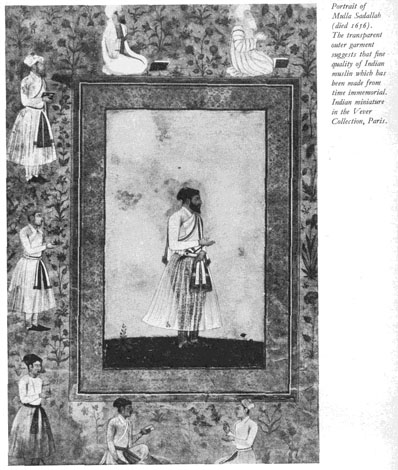

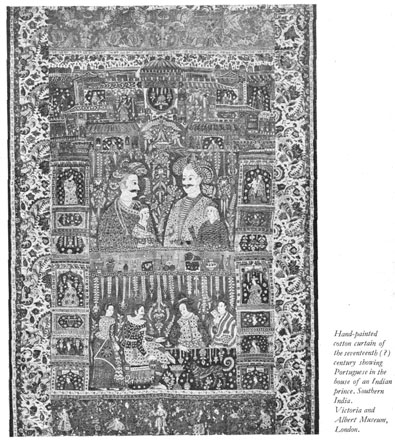

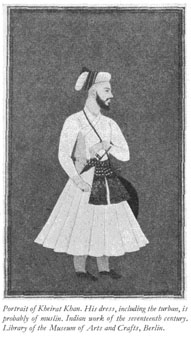

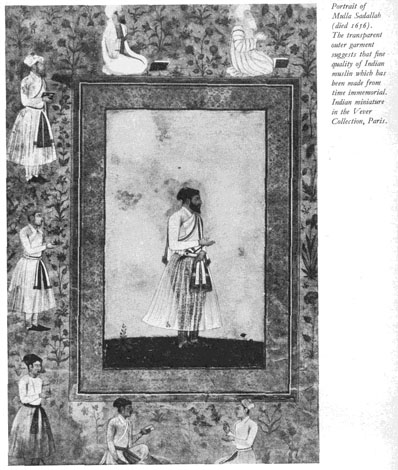

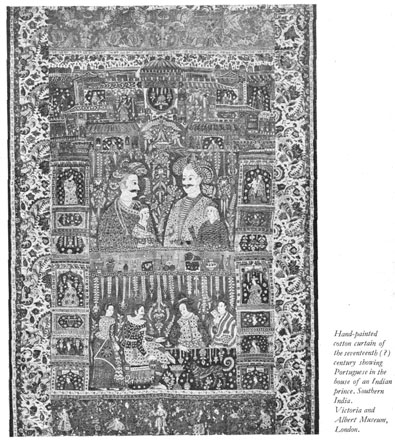

That work of superior quality was done on the east coast was confirmed by Marco Polo as late as the thirteenth century; he reported that he had seen on the Coromandel coast the finest and most beautiful cotton cloth to be found in all the world. The Ancients tell astonishing stories of the value of these Indian fabrics. There can be no doubt that they were known to Rome, and were numbered among the most coveted articles in the elegant and luxurious capital. Quintus Curtius Rufus (first half of the first century A.D.) described a cotton robe of an Indian prince as being spotted with purple and gold. According to Lucan (A.D. 39-65) the Indians fastened robes made of these light flowing fabrics with precious stones of different colours. The texture of the material was so delicate that the poets described them as "woven wind". Many centuries later one of the Portuguese navigators wrote: "When muslin of this kind is spread out on the grass to bleach, and when it is wet with dew, the cloth is no longer visible." The whiteness of Indian cottons was repeatedly praised, and was apparently regarded as their distinctive feature throughout the ancient world. It was not until the time of the Portuguese seamen that painted fabrics were mentioned, the designs sometimes being executed on a white and sometimes on a striped ground.

That work of superior quality was done on the east coast was confirmed by Marco Polo as late as the thirteenth century; he reported that he had seen on the Coromandel coast the finest and most beautiful cotton cloth to be found in all the world. The Ancients tell astonishing stories of the value of these Indian fabrics. There can be no doubt that they were known to Rome, and were numbered among the most coveted articles in the elegant and luxurious capital. Quintus Curtius Rufus (first half of the first century A.D.) described a cotton robe of an Indian prince as being spotted with purple and gold. According to Lucan (A.D. 39-65) the Indians fastened robes made of these light flowing fabrics with precious stones of different colours. The texture of the material was so delicate that the poets described them as "woven wind". Many centuries later one of the Portuguese navigators wrote: "When muslin of this kind is spread out on the grass to bleach, and when it is wet with dew, the cloth is no longer visible." The whiteness of Indian cottons was repeatedly praised, and was apparently regarded as their distinctive feature throughout the ancient world. It was not until the time of the Portuguese seamen that painted fabrics were mentioned, the designs sometimes being executed on a white and sometimes on a striped ground.

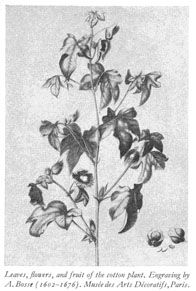

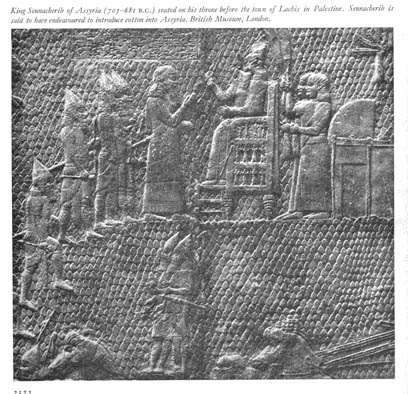

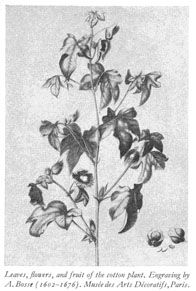

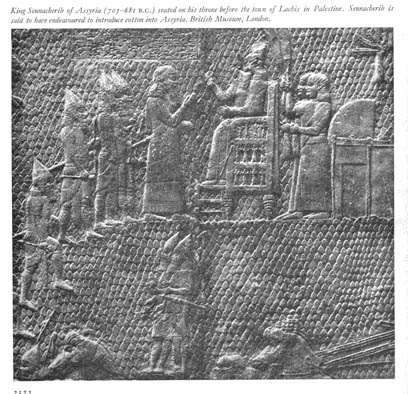

India's share in the history of the cotton industry can thus be estimated fairly accurately; with regard to the extent of this branch of the textile crafts in other countries of the ancient world our knowledge is scanty. It is believed that the processing of cotton gradually spread westward to the shores of the Mediterranean. Strabo (63 B.C-A.D. 19) mentions the occurrence of cotton in the district of the Persian Gulf, and there can be little doubt that the workshops of Borsippa, a suburb of Babylon, which became famous at an early date, also produced cotton goods. Authentic reports of cotton growing on the Island of Tylos were given by Theophrastus. He described the cotton plant as a shrub with leaves similar to those of the vine and with capsules about the size of a quince. When the capsules were ripe, they burst open; they contained seeds surrounded by a kind of wool which was woven into fabrics of both fine and inferior quality. Though this obviously well informed report does not state expressly that the processing of the fibre was carried on at the same place, it may be inferred that workshops existed on the island.

India's share in the history of the cotton industry can thus be estimated fairly accurately; with regard to the extent of this branch of the textile crafts in other countries of the ancient world our knowledge is scanty. It is believed that the processing of cotton gradually spread westward to the shores of the Mediterranean. Strabo (63 B.C-A.D. 19) mentions the occurrence of cotton in the district of the Persian Gulf, and there can be little doubt that the workshops of Borsippa, a suburb of Babylon, which became famous at an early date, also produced cotton goods. Authentic reports of cotton growing on the Island of Tylos were given by Theophrastus. He described the cotton plant as a shrub with leaves similar to those of the vine and with capsules about the size of a quince. When the capsules were ripe, they burst open; they contained seeds surrounded by a kind of wool which was woven into fabrics of both fine and inferior quality. Though this obviously well informed report does not state expressly that the processing of the fibre was carried on at the same place, it may be inferred that workshops existed on the island.

Opinions differ considerably with regard to the time when cotton spinning first began to be practised among the Semitic peoples. Strabo stated that the cotton shrub with which he was familiar also occurred in Arabia, and later evidence shows that the methods of processing the fibre were known there. Late in the twelfth century Chao Jon Koua, the inspector of Chinese foreign trade, reported that Arab caravans brought fine cotton goods to the ports of the Persian Gulf, where they were loaded on ships together with the madder plant used for scarlet dyeing. The herbal of Prosper Alpinus, which dates from the sixteenth century, mentions the extremely fine texture of the cotton cloths woven by the Arabs; they were known as "sessa", and their beauty was universally praised. The assertion that such fabrics had been manufactured for more than a thousand years before that time and that they had been objects of trade between the Arabs and the Phoenicians has yet to be proved. In his history of the Phoenicians Movers states that the wealthy Arab tribes supplied large quantities of cotton fabrics which were traded by the Phoenicians both in the Orient and in the West together with rare silks, purple fabrics, and fine linen.

The same author suggests that the mention of cotton weavers in the Bible warrants the assumption that this trade existed in pre-Hebraic times. The family of Byssos workmen belonging to the tribe of Juda which is mentioned in the First Book of Chronicles bore a Canaanite name, which Movers interpreted as indicating a tradition of cotton weaving among the original inhabitants of that country. If the word Byssos really did mean the cotton shrub, which appears highly probable in view of later descriptions such as that of Pausanius, the assumption of Jewish cotton trade may be justified, particularly as the Talmud not only refers to the occurrence of the plant, but also to Byssos merchants in Judaea. Nevertheless, it must remain an open question whether the materials described in the Bible as "shech"--these are frequently mentioned in the Books of Moses--were of native origin or whether they formed part of the Indian goods which doubtless found their way to the countries of the Near East. The robe presented to Joseph by the King of Egypt when he was given the ring and gold necklace and made ruler of Egypt, is described as something very costly indeed; Aaron, the high priest, and his sons wore robes and head-coverings of shech, and the curtain before the cherubim in the Holy of Holies of the Temple was described as being of purple, scarlet, crimson, and white shech. This description has led several scholars to believe that the material of this curtain must surely have been cotton, as cotton only, and not linen, assumes such wonderful, brilliant colours when dyed.

The same author suggests that the mention of cotton weavers in the Bible warrants the assumption that this trade existed in pre-Hebraic times. The family of Byssos workmen belonging to the tribe of Juda which is mentioned in the First Book of Chronicles bore a Canaanite name, which Movers interpreted as indicating a tradition of cotton weaving among the original inhabitants of that country. If the word Byssos really did mean the cotton shrub, which appears highly probable in view of later descriptions such as that of Pausanius, the assumption of Jewish cotton trade may be justified, particularly as the Talmud not only refers to the occurrence of the plant, but also to Byssos merchants in Judaea. Nevertheless, it must remain an open question whether the materials described in the Bible as "shech"--these are frequently mentioned in the Books of Moses--were of native origin or whether they formed part of the Indian goods which doubtless found their way to the countries of the Near East. The robe presented to Joseph by the King of Egypt when he was given the ring and gold necklace and made ruler of Egypt, is described as something very costly indeed; Aaron, the high priest, and his sons wore robes and head-coverings of shech, and the curtain before the cherubim in the Holy of Holies of the Temple was described as being of purple, scarlet, crimson, and white shech. This description has led several scholars to believe that the material of this curtain must surely have been cotton, as cotton only, and not linen, assumes such wonderful, brilliant colours when dyed.

Oddly enough, the most violent controversies have arisen over the question of cotton growing in Ancient Egypt, though Roman sources at least contain most unequivocal evidence. The dispute probably originated in the fact that the terms in use for linen and cotton were not always clearly distinguished; very often the word "Byssos" was used for any kind of woven fabric of finer texture. Furthermore, the examination of mummy wrappings did much to increase the uncertainty caused by written records. On examination of the fabrics in which the Egyptians were in the habit of wrapping their dead, some experts described them as being of linen, whilst others believed them to be of cotton. As regards the latter opinion, it has been almost universally abandoned. Finally, the opponents of the cotton theory stressed the fact that Egypt had always been the country of flaxgrowing and of the linen industry, so that tradition must have been very strongly opposed to the introduction of new textiles which were more expensive than linen.

When we consult classical records in this matter, it would be unwise to lay too much stress on the statement of Herodotus, who says that the coat of mail which Amasis presented to the Lacedaemonians was decorated with many woven figures of animals, and was "ornamented with gold and the wool of trees". Though it is not entirely impossible that cotton threads may have been used in weaving these figures, the explanation given by Yates, the author of the "Textrinum Antiquorum" appears more probable. Yates is of the opinion that the gold ornaments were underlaid with a kind of cotton still used in India for filling cushions etc., but not for weaving. The information given by Pliny is more valuable. Though he obviously based his report on the cotton plant on Theophrastus, the following passage may be regarded as the result of direct observation: "The upper part of Egypt which is directed towards Arabia produces a shrub called "gossipion" by some and "xylon" by others, for which reason the fabrics made from that shrub have received the name "xylina". Its fruit resembles a bearded nut, the inner fibre of which is spun like wool; it is a wool second to none in whiteness and softness of texture. It supplies the priests of Egypt with their favourite kind of dress." In his book on Egyptian plants, which was published in 1592, Prosper Alpinus

describes the cotton tree, gossypium arboreum, as being distinguished by its height and the whiteness of its fibres from the shrub-like plant, planta herbacea, which grows in Syria.

When we consult classical records in this matter, it would be unwise to lay too much stress on the statement of Herodotus, who says that the coat of mail which Amasis presented to the Lacedaemonians was decorated with many woven figures of animals, and was "ornamented with gold and the wool of trees". Though it is not entirely impossible that cotton threads may have been used in weaving these figures, the explanation given by Yates, the author of the "Textrinum Antiquorum" appears more probable. Yates is of the opinion that the gold ornaments were underlaid with a kind of cotton still used in India for filling cushions etc., but not for weaving. The information given by Pliny is more valuable. Though he obviously based his report on the cotton plant on Theophrastus, the following passage may be regarded as the result of direct observation: "The upper part of Egypt which is directed towards Arabia produces a shrub called "gossipion" by some and "xylon" by others, for which reason the fabrics made from that shrub have received the name "xylina". Its fruit resembles a bearded nut, the inner fibre of which is spun like wool; it is a wool second to none in whiteness and softness of texture. It supplies the priests of Egypt with their favourite kind of dress." In his book on Egyptian plants, which was published in 1592, Prosper Alpinus

describes the cotton tree, gossypium arboreum, as being distinguished by its height and the whiteness of its fibres from the shrub-like plant, planta herbacea, which grows in Syria.

The same differences are stressed by Pollux, a writer who lived at the end of the second century of the Christian era. He compared the fruit of the cotton tree with a walnut divided into three sections. When the shell bursts open, the wool-like substance is taken out and used for spinning the weft-threads of a fabric, the warp of which consisted of linen threads. This was the first time that a mixed fabric of cotton and linen was described, a fabric which at a later date was to be the most important product of the early cotton industry in Europe. The fact that Pollux described a new fabric which differed materially from the muslins of India is confirmed by a statement made elsewhere, according to which Egyptian cotton cloths were thicker than linen, and were used in making coats and capes. The Romans must have been familiar with these fabrics; a contemporary report has been interpreted as stating that the army of Mark Anthony in Egypt (first century B.C.) wore light cotton cloths as a protection against the sun. We also hear of the use of cotton cloth for a similar purpose in Italy, where Verres, the pro-praetor of Sicily ( to 71 B.C.) used cotton as a tent-cloth, and where the theatre was covered with a cotton tent to guard against the rays of the sun.

The fact that a duty on cotton is mentioned in Roman laws indicates that certain quantities must have been imported; these imports were probably from Asia Minor and Greece; there is no record of cotton having been spun or woven on Roman soil, with the exception of the unconfirmed report concerning Malta (see Ciba Review No. 9, page 296). The high price of this foreign product made it difficult for the cotton spinning and weaving trade to develop to any great extent, for cotton as compared with wool and linen had the character of a luxury article. Greece produced a cotton product which the Romans paid for with its weight in gold. Pausanias (second century A.D.) reports that the women of Patrae gained their livelihood by weaving fabrics and hair-nets out of the Byssos wool which grew in Elis. Pausanias distinguished these fibres so plainly from hemp and flax that there can be very little doubt that the term "Byssos" as used in this connection refers to cotton. He compared the fibre with that of the Syrian plant, saying that it was in no way inferior in fineness of texture, the only difference being that it had not the yellowish shade of Syrian cotton. From this latter remark we may infer that he meant the weed-like cotton plant which still grows in the swampy lowlands of Greece. The Corpus iuris mentions in addition to carbasum and carbasca (cotton fabrics and cotton thread) a third variety, opus byssium, a heading under which various articles made of cotton were classed, among them the hair-nets of Patrae. In medieval records cotton of Macedonia and Thessalia and cotton-growing on the shores of the Black Sea are frequently mentioned; in spite of this we have no detailed knowledge of the cotton industry in Eastern Europe at that time; on the contrary it appears that the industry gradually spread across Europe from the West.

The Beginnings of the Cotton Industry in Europe

by H. Wescher

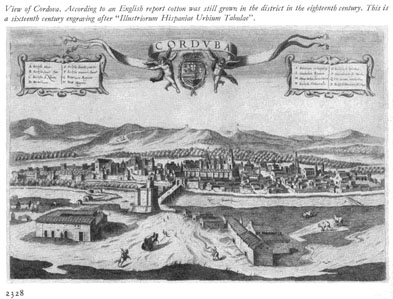

As far as we know today cotton growing and spinning spread from Spain to the rest of Europe. It is true that Pliny's reference to the flourishing weaving trade at Taragona can scarcely be interpreted as including cotton weaving, but at the time of Mohammedan rule cotton garments are certainly mentioned. In his history of Spain De Marles stated that the Moors brought the cotton plant with them across the Mediterranean together with the sugar cane and the mulberry. The climate was favourable to cotton growing, and Oliva and Candea soon became famous as flourishing centres of cotton planting. The "Liber de Agricultura" of Ibn al Awam, which was published in the twelfth century, and which, according to the author's own statement, was based on earlier Moorish writings, contains a number of important rules for growing cotton which impart some information on the practical aspects of this branch of agriculture at that time. The author based his observations on the experience of other countries, particularly of Arabia, Egypt, and Syria, giving a number of useful hints as to the observation of seasons and weather when sowing and tending the plant, and also for the harvest. According to Ibn al Awam the picking and opening of the pods should take place in the shade, whilst the fibre was to be dried in the sun. Great attention was devoted to the problem of irrigation, on which crops were very much dependent when grown in the sandy soil of Spain or in Sicily.

As far as we know today cotton growing and spinning spread from Spain to the rest of Europe. It is true that Pliny's reference to the flourishing weaving trade at Taragona can scarcely be interpreted as including cotton weaving, but at the time of Mohammedan rule cotton garments are certainly mentioned. In his history of Spain De Marles stated that the Moors brought the cotton plant with them across the Mediterranean together with the sugar cane and the mulberry. The climate was favourable to cotton growing, and Oliva and Candea soon became famous as flourishing centres of cotton planting. The "Liber de Agricultura" of Ibn al Awam, which was published in the twelfth century, and which, according to the author's own statement, was based on earlier Moorish writings, contains a number of important rules for growing cotton which impart some information on the practical aspects of this branch of agriculture at that time. The author based his observations on the experience of other countries, particularly of Arabia, Egypt, and Syria, giving a number of useful hints as to the observation of seasons and weather when sowing and tending the plant, and also for the harvest. According to Ibn al Awam the picking and opening of the pods should take place in the shade, whilst the fibre was to be dried in the sun. Great attention was devoted to the problem of irrigation, on which crops were very much dependent when grown in the sandy soil of Spain or in Sicily.

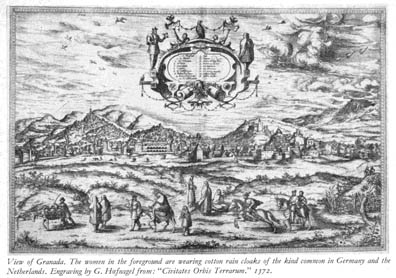

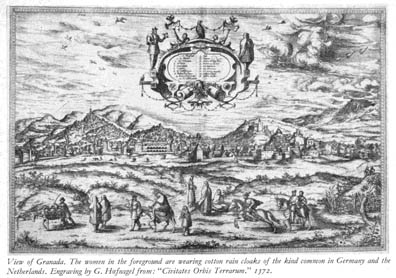

As a result of such detailed study, cotton growing in Spain soon began to flourish, and maintained its position for many centuries. As late as the eighteenth century the English traveller Richard Twiss described the cotton fields on either side of the road from Cordova to Ecija with the yellow and red blossoms of the plants, and he wrote with admiration of the rich crop yielded every year by the plantations. These cotton plantations contributed at an early date to the fame of the workshops of Granada. When Abderrahman III (912 to 961) began to restore the prosperity of the country after the ravages of war, and to revive industries which had declined ever since the period of Roman occupation, Arabs and Moors were commissioned to instruct the natives in the various trades. One craft in which they excelled was leather working, another was weaving, which they practised with equal skill in silk, flax, hemp, and cotton. In the fourteenth century cotton cloth was made in Granada which was used as a dress material, and which in the opinion of Ibn Alchabid, who wrote a history of Granada, at that time was superior in softness, purity of material, and in beauty to the fabrics of Syria. The dye used in dyeing this material was madder.

In Christian Catalonia, too, cotton weaving must have been established at an early date. Already in the thirteenth century the "fustaneros", the weavers of fustian, were organized in a guild, and old street names show to this day where they carried on their trade. In some towns the weavers were obliged to transfer their activities to the outskirts of the town, as the neighbours complained to the municipal authorities of the annoyance caused to them by the proximity of the workshops. Fourteenth century laws not only inform us that the sale of fustian was under official supervision, we also learn something of the regulations which the dyers of these fabrics had to observe. Records of the activities of the fustaneros take us down to the fifteenth century; for the most part these records are regulations for the sale of pure cotton or mixed fabrics and also penalties for bad work. It would appear that this branch of the Spanish textile crafts did not survive the fifteenth century; it seems to have been replaced by the silk industry which began to prosper greatly about that time.

In Italy both raw cotton and fustian are mentioned in the trade registers of Genoa from the twelfth century on. In 1140 already the lists of the public weights mention "bombacium di Sicilia" in addition to cotton from Alexandria and Antiochia. In a contract of 1593 cotton takes first place among a list of goods to be sent from Genoa to Lodi; a year prior to that date the Customs lists mentioned raw cotton and also cotton fabrics under the unmistakable name of "somma fustaniorum". Genoese trade records of the year 1204 also mention cotton bales. It may, therefore, be assumed with a certain probability that these entries refer to products of the Italian industries. From Romagna, where cotton cloths are said to have been woven ever since the earliest times, the industry spread to Tuscany.

In Italy both raw cotton and fustian are mentioned in the trade registers of Genoa from the twelfth century on. In 1140 already the lists of the public weights mention "bombacium di Sicilia" in addition to cotton from Alexandria and Antiochia. In a contract of 1593 cotton takes first place among a list of goods to be sent from Genoa to Lodi; a year prior to that date the Customs lists mentioned raw cotton and also cotton fabrics under the unmistakable name of "somma fustaniorum". Genoese trade records of the year 1204 also mention cotton bales. It may, therefore, be assumed with a certain probability that these entries refer to products of the Italian industries. From Romagna, where cotton cloths are said to have been woven ever since the earliest times, the industry spread to Tuscany.

It existed at Cortona from 1274 on, and attained considerable importance at Arezzo during the thirteenth century. In Florence itself the trade with fustians appears to have been more important than the products of the city's own cotton looms. Nevertheless cotton, which was imported from Sicily by the firm of Peruzzi before 1278, was used by the textile industry; borders of a certain kind were made of a mixture of animal and vegetable fibres. In addition waste cotton and old cotton materials were imported into Florence to be used for stuffing bed-quilts and for lining winter clothing.

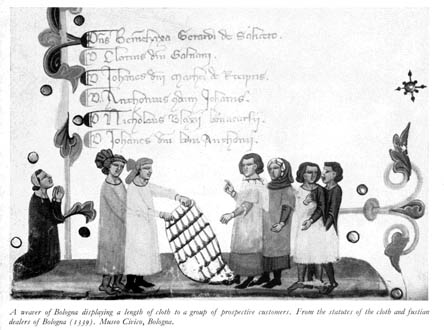

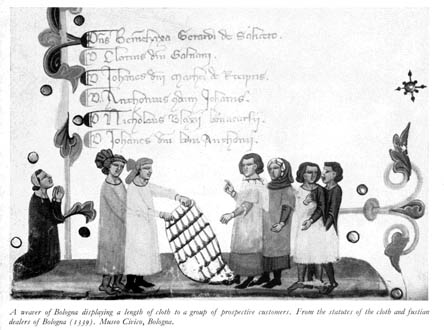

To the north of Tuscany cotton weaving soon assumed considerable magnitude. Tradition has it that imported raw cotton was woven in Bologna as early as the end of the twelfth century. Like their Venetian colleagues, the fustian weavers had their own guild in the thirteenth century. Cotton weaving was established in Padua in 1265, and Rimini soon followed suit. It would appear that the new industry was unable to compete seriously with the existing linen, wool, and silk weaving trades in these towns. Its position became much stronger in the district of Milan. Cotton had been woven and spun in Milan from a very early period. Considerable textile factories were established at Bergamo and Cremona, and detailed regulations concerning the trade in Piacenra have been preserved.

Statutes of the year 1331 record the manufacture of fustian at Monza, and lists of the taxes paid by this trade in 1335 show that it flourished in Como in the fourteenth century. In Milan the guild of "fustagnari" must have existed before 1347. The statutes of the guild were laid down in 1360, and were revised or completely renewed in 1385, 1414, and 1467. One of these regulations mentions the "batitores bombacis" or cotton beaters, which appear there for the first time as independent craftsmen beside the weavers. The number of workshops must have been quite considerable, and they appear to have provided a large proportion of the population with a livelihood, in 1385 the masters of the guilds decreed that no workman might be employed fourteen days before or after Michaelmas; this was to ensure that all might be available to assist at the grape harvest. When the "tessitori and fabbricatori" protested against this regulation on the grounds that they neither all owned vineyards nor could find employment there, their protest was upheld by the authorities.

Statutes of the year 1331 record the manufacture of fustian at Monza, and lists of the taxes paid by this trade in 1335 show that it flourished in Como in the fourteenth century. In Milan the guild of "fustagnari" must have existed before 1347. The statutes of the guild were laid down in 1360, and were revised or completely renewed in 1385, 1414, and 1467. One of these regulations mentions the "batitores bombacis" or cotton beaters, which appear there for the first time as independent craftsmen beside the weavers. The number of workshops must have been quite considerable, and they appear to have provided a large proportion of the population with a livelihood, in 1385 the masters of the guilds decreed that no workman might be employed fourteen days before or after Michaelmas; this was to ensure that all might be available to assist at the grape harvest. When the "tessitori and fabbricatori" protested against this regulation on the grounds that they neither all owned vineyards nor could find employment there, their protest was upheld by the authorities.

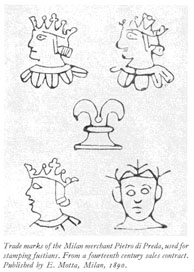

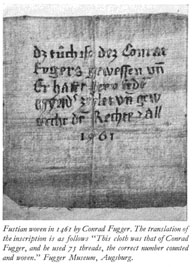

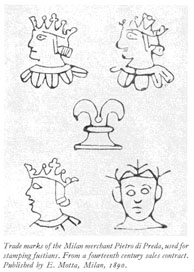

The sale of fustians was restricted to fixed days and places. The finished goods not only had to bear the stamp of the municipal comptroller, they were also distinguished by the trade mark of the manufacturer (see Ciba Review No. 13, page 446 et seq.), which was entered in the books of the guild. Some of these stamps are known to us from a contract of remarkably modern character which dates from the year 1383. According to this contract Pietro Tanzio, a manufacturer of Milan, paid a hundred forms of good silver money for the right to adopt the stamps used in marking the cotton cloths of Pietro di Preda, apparently a manufacturer of good reputation, in order to be better able to dispose of his goods. Different kinds and qualities of cotton appear to have been traded at that time; we hear of white and dyed cloths and of others woven from coloured threads. The price lists of the firm of Giovanni and Lucchino Visconti distinguished between "fustagno alto e basso" for the export and import duties of Milan.

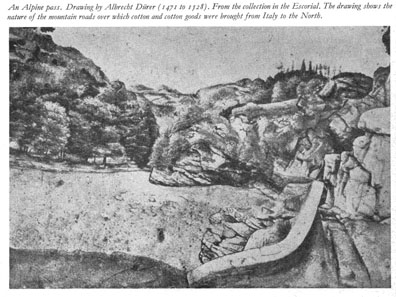

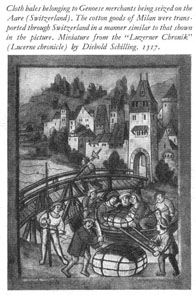

Exports of Milan fustian increased rapidly from the fourteenth century on. A duty of twelve denarii "pro libra precii fustaneorum" yielded to Genoa a revenue of 500-700 pounds yearly between 1354 and 1377; this corresponds to an import value of 1300-1800 pounds for the fabrics. The goods were sold at the Fairs of South Germany and Switzerland, and they very often took first place in the contracts concerning the transport of merchandise over the Simplon Pass. As late as the sixteenth century many kinds of single and double Milan fustians were mentioned among the goods imported into Antwerp. Merchants of every country in Europe came to Milan to do business there, and there are innumerable documents concerning the settlement of differences between the textile merchants of Milan and their foreign customers. The fact that merchants of Constance and Basle were numbered among these customers may not have been without significance for the transplanting of this branch of trade to northern countries.

Exports of Milan fustian increased rapidly from the fourteenth century on. A duty of twelve denarii "pro libra precii fustaneorum" yielded to Genoa a revenue of 500-700 pounds yearly between 1354 and 1377; this corresponds to an import value of 1300-1800 pounds for the fabrics. The goods were sold at the Fairs of South Germany and Switzerland, and they very often took first place in the contracts concerning the transport of merchandise over the Simplon Pass. As late as the sixteenth century many kinds of single and double Milan fustians were mentioned among the goods imported into Antwerp. Merchants of every country in Europe came to Milan to do business there, and there are innumerable documents concerning the settlement of differences between the textile merchants of Milan and their foreign customers. The fact that merchants of Constance and Basle were numbered among these customers may not have been without significance for the transplanting of this branch of trade to northern countries.

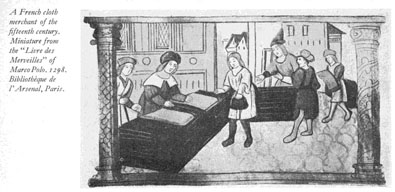

On French soil, too, such fustians ("futaines") are mentioned early in the Middle Ages. They first appeared at the Fairs of Champagne, without it being possible to say where they came from. These Fairs, which alternated between the four towns of Troyes, Provins, Bar-sur-Aube, and Lagny, formed the centres of commerce and finance for continental trade from the twelfth to the fourteenth century. Merchants of Provence and Italy met men from the North of France, from Flanders and England, and exchanged their wares. German merchants, who had their own offices and warehouses in the different towns, took an active part in the trade, and visitors came from Spain and even from Acre for the express purpose of attending the Fairs. Though woollen and silk materials made up the bulk of the goods handled at these Fairs, fustians also find mention. According to a document of 1163, Count Henri Le Liberal handed over to a certain Habran of Provins the house in which fustians were sold at the Martinmas Fair, and he also decreed that no fustians should be sold elsewhere before that house was filled. In 1179 the same nobleman confirmed a donation consisting of one third of the fustian duties which was made to the Church of Bar-sur-Aube; he also bequeathed to the clergy all his rights to this duty.

Merchants of Provence and Italy met men from the North of France, from Flanders and England, and exchanged their wares. German merchants, who had their own offices and warehouses in the different towns, took an active part in the trade, and visitors came from Spain and even from Acre for the express purpose of attending the Fairs. Though woollen and silk materials made up the bulk of the goods handled at these Fairs, fustians also find mention. According to a document of 1163, Count Henri Le Liberal handed over to a certain Habran of Provins the house in which fustians were sold at the Martinmas Fair, and he also decreed that no fustians should be sold elsewhere before that house was filled. In 1179 the same nobleman confirmed a donation consisting of one third of the fustian duties which was made to the Church of Bar-sur-Aube; he also bequeathed to the clergy all his rights to this duty.

These records appear to confirm Bourquelot-who wrote the history of these French Fairs-in the opinion that the fabrics mentioned were of native origin. In the thirteenth century 3200 looms were in operation in the town of Provins; it may, therefore, be assumed that in addition to "draps et serges", cotton cloths or "futaines et mollequins" were made.

Though imports of cotton are mentioned occasionally in France during the fourteenth century, the processing of this textile raw material does not appear to have progressed much farther. In the accounts of the Royal household the purchase of four pounds of cotton is mentioned which were required for repairing the mattress of the King's bed; for this quantity four sols and six deniers were paid. According to a very vague report, fabrics known as "bourras" are said to have been made at Lille about that time; they are believed to have been woven of a mixture of wool and cotton.

According to another tradition cotton was introduced into Dieppe in 1362, into Harfleur in 1387, where it is said to have been used in the manufacture of candle wicks, gloves, and bonnets. The use of cotton for candle wicks is repeatedly mentioned; as compared with animal fibre cotton had the advantage of leaving no smell when burnt. In Northern France the processing of cotton was not placed in the hands of the weavers guilds; this is shown by a Royal charter of the year 1536 in which Francis I granted to the passement weavers of Rouen a monopoly of cotton weaving, as they were the first who had attempted the manufacture of fringed and roughened fustians (futaines frang&eacut;es et velues). These fabrics, which were chiefly designed for export, are expressly described in the document as novelties.

According to another tradition cotton was introduced into Dieppe in 1362, into Harfleur in 1387, where it is said to have been used in the manufacture of candle wicks, gloves, and bonnets. The use of cotton for candle wicks is repeatedly mentioned; as compared with animal fibre cotton had the advantage of leaving no smell when burnt. In Northern France the processing of cotton was not placed in the hands of the weavers guilds; this is shown by a Royal charter of the year 1536 in which Francis I granted to the passement weavers of Rouen a monopoly of cotton weaving, as they were the first who had attempted the manufacture of fringed and roughened fustians (futaines frang&eacut;es et velues). These fabrics, which were chiefly designed for export, are expressly described in the document as novelties.

If the cotton industry developed so late in Northern France, it may be confidently assumed that the industry had already become native to the neighbouring country of Flanders. The first mention of cotton goods is contained in the broker's records of the Countess Margaret of Flanders of 1252, and at the end of the thirteenth century Armenia occurs in a list of the countries which supplied the great trading centre of Bruges with cotton. The official records of that town of the year 1304 mention both bales of cotton thread and of raw cotton as part of the goods brought by foreign merchants to the city. Flemish fustians, which are frequently mentioned, and the manufacture of which in Ghent is described by Guicciardini, must have acquired fame in the fourteenth century, for we learn that they were being imitated in England a century later. Records of the Hanseatic League refer to an attempt of the weavers of Chester and Lancashire in 1430 to use cotton for coarse fabrics similar to Flemish fustians, and they add that the success of these experiments induced merchants of London and Bristol to send ships to the Levant to procure raw cotton, thread, or finished fabrics. Apart from such mention we know nothing of the cotton industry of England until the imports of "indiennes" (chintz) gave it its first great stimulus.

This development began in 1664 with the establishment by the East India Company of an English trading settlement in Calicut; that is to say, much later than in France, where the cotton industry suddenly began to flourish at the end of the sixteenth century. The first factory was founded at Lyons in 1580; and two years later it already numbered 2000 workmen, among whom the Italians were predominant. This foundation and another one at Troyes in 1582 are no part of the present study, but belong rather to the history of modern industry.

Cotton Growing and Cotton Trade in the Orient During the Middle Ages

By H. Wescher

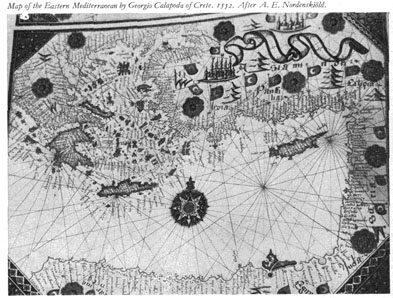

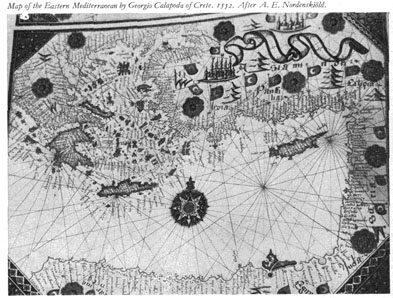

Ever since cotton has been grown in India it has been shipped as merchandise all over the world. Arrianus' "Periplus Mans Erythraei" contains a description of the trade relations between Indians and Arabs in the Red Sea, and mentions Adulis as the principal centre of the cotton trade. There can be no doubt that Indian merchandise was also transported via the caravan routes. In the Far East cotton-growing was not begun until comparatively late; in the thirteenth century Marco Polo saw cotton plantations in the Chinese province of Fukien. In the Near East, cotton began to be planted in the first centuries of the Christian era, becoming firmly established in Persia, Armenia, Syria, and Asia Minor. The cotton produced in those countries soon became a factor of great importance, not only because climate and soil were particularly favourable, but above all because of the exceptional advantages of the geographical situation, which became increasingly important, the more European trade with the Orient developed.

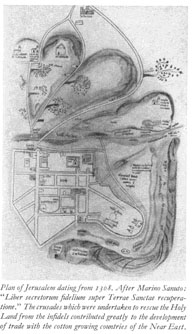

The crusades and pilgrimages to the Holy Land were not only expressions of the fervent piety of medieval Europe, they also served as an outlet for the spirit of business enterprise which was particularly strong in the merchant cities of Italy. They signified the beginning of a period of commercial relations between Europe and the Levant, in which cotton was an important item. On a pilgrimage undertaken in 1211 Wilbrand of Oldenburg saw the cotton plant growing in the country north of ancient Tripolis (Syria); both cotton and silk were shipped from the port of Beirut. The excise lists of the kingdom of Jerusalem from the earliest times included both raw cotton and cotton cloth. The Christian merchants did not at first venture into the interior of the heathen countries where cotton grew; they found all they required in the markets of the Christian states. In Acre, Laodicea, and Jaffa they loaded their ships with "bombacium de ultra mare", as cotton was called. At a later period trade agreements with the Sultans of Egypt, who were also the rulers of Syria, gave the Venetians access to the most important cities under Saracen rule. Already in the first half of the thirteenth century Venetian merchants visited Damascus; in 1207 P. Marignoni was the ambassador of the Doge Ciani to the Prince of Haleb (Aleppo) a son of Saladin, with whom he negotiated a commercial treaty. The prince granted the Venetians permission to maintain a church, a hostel, and baths, and guaranteed that all who settled at Aleppo or Laodicea should enjoy the protection of the law for themselves and their property. Detailed regulations concerning the dues which were to be paid on the outgoing goods were drawn up. Among the goods mentioned were pearls, precious stones, and cotton, for which latter a fixed sum was to be paid on every load leaving the city gate. Another ambassador, Tomasino Foscarini, who was sent in 1225 with a message to the lord of Sehjun, who ruled in northern Syria, and dominated the caravan route to Haleb (Aleppo), succeeded in obtaining a reduction of the duty on pepper and cotton.

The crusades and pilgrimages to the Holy Land were not only expressions of the fervent piety of medieval Europe, they also served as an outlet for the spirit of business enterprise which was particularly strong in the merchant cities of Italy. They signified the beginning of a period of commercial relations between Europe and the Levant, in which cotton was an important item. On a pilgrimage undertaken in 1211 Wilbrand of Oldenburg saw the cotton plant growing in the country north of ancient Tripolis (Syria); both cotton and silk were shipped from the port of Beirut. The excise lists of the kingdom of Jerusalem from the earliest times included both raw cotton and cotton cloth. The Christian merchants did not at first venture into the interior of the heathen countries where cotton grew; they found all they required in the markets of the Christian states. In Acre, Laodicea, and Jaffa they loaded their ships with "bombacium de ultra mare", as cotton was called. At a later period trade agreements with the Sultans of Egypt, who were also the rulers of Syria, gave the Venetians access to the most important cities under Saracen rule. Already in the first half of the thirteenth century Venetian merchants visited Damascus; in 1207 P. Marignoni was the ambassador of the Doge Ciani to the Prince of Haleb (Aleppo) a son of Saladin, with whom he negotiated a commercial treaty. The prince granted the Venetians permission to maintain a church, a hostel, and baths, and guaranteed that all who settled at Aleppo or Laodicea should enjoy the protection of the law for themselves and their property. Detailed regulations concerning the dues which were to be paid on the outgoing goods were drawn up. Among the goods mentioned were pearls, precious stones, and cotton, for which latter a fixed sum was to be paid on every load leaving the city gate. Another ambassador, Tomasino Foscarini, who was sent in 1225 with a message to the lord of Sehjun, who ruled in northern Syria, and dominated the caravan route to Haleb (Aleppo), succeeded in obtaining a reduction of the duty on pepper and cotton.

The Customs regulations made a distinction between camel-loads, the characteristic of the wholesale export trade, and mule-loads, which were the rule where trade was on a more modest scale. In the course of time the dues payable on mule-loads were considerably reduced by the Oriental princes, in order to induce travelling merchants to visit their countries. These merchants brought European textiles, silver, and copper, which they exchanged for cotton and spices of every kind. Cotton and spices were so closely linked in the minds of Europeans that Basic accountbooks of the period often list cotton under the heading "spices", the latter term being synonymous with Venetian goods.

Just as Damascus was at that time the principal market for the interior of Asia, to which caravans made their way via Baghdad through Mesopotamia, Mecca, and Ephesos were of importance for the Arabian and Turkish commercial areas respectively. In Ephesos, where a new city had grown up round the early Christian centre, the ancient church of St. John served as a hall where cotton, wool, and grain were sold; in the chancel the tomb of the apostle was shown to visitors on payment of a fee.

After the fail of Acre in 1291 there came a temporary break in the trade with Europe. Marino Sanuto, a Venetian chronicler who wrote a "Liber secretorum fidelium super Terrae Sanctae recuperatione", by means of which he sought to rouse Europe for a further crusade, strove to restrain the merchants of his country from buying cotton from the infidels. He pointed out that cotton was also to be had in Christian countries, not only in Lesser Armenia and Cyprus, but in Apulia, Sicily, Crete, and Romagna. Of European cottons that of Crete formed an item of Venetian trade, being imported together with dyes, kermes, and ladanum gum; the Western world was, however, unwilling to be without the products of Syrian cotton. From that time on, the transit trade between Syria and Europe was centred in Armenia and Cyprus. A journey made by a merchant of Barcelonain defiance of the decrees of the Church from Cyprus to Syria in 1335 for the purpose of trading with the Saracens in Damascus was an isolated occurrence, and does not appear to have been taken as an example. We have records of two Venetian merchants, Michiel and Morosoni, who went to Lajazzo, the port of Lesser Armenia, in 1298 to buy six bales of ginger and eighteen sacks of cotton from Aleppo. Between 1391 and 1394 three ships sailed to Famagusta, the port of Cyprus, with cargoes of French, Flemish, Spanish, and Florentine cloth, French linen, as well as iron, tin, and coral. In exchange they traded spices, pepper, and sugar, furthermore cotton and Oriental fabrics, such as bocasin (a species of fine buckram), camlet, camoca, and gold brocade, as well as gold thread and jewels. The captains were commissioned to procure as large a quantity of spices as possible and then cotton, which was a less valuable commodity.

After the fail of Acre in 1291 there came a temporary break in the trade with Europe. Marino Sanuto, a Venetian chronicler who wrote a "Liber secretorum fidelium super Terrae Sanctae recuperatione", by means of which he sought to rouse Europe for a further crusade, strove to restrain the merchants of his country from buying cotton from the infidels. He pointed out that cotton was also to be had in Christian countries, not only in Lesser Armenia and Cyprus, but in Apulia, Sicily, Crete, and Romagna. Of European cottons that of Crete formed an item of Venetian trade, being imported together with dyes, kermes, and ladanum gum; the Western world was, however, unwilling to be without the products of Syrian cotton. From that time on, the transit trade between Syria and Europe was centred in Armenia and Cyprus. A journey made by a merchant of Barcelonain defiance of the decrees of the Church from Cyprus to Syria in 1335 for the purpose of trading with the Saracens in Damascus was an isolated occurrence, and does not appear to have been taken as an example. We have records of two Venetian merchants, Michiel and Morosoni, who went to Lajazzo, the port of Lesser Armenia, in 1298 to buy six bales of ginger and eighteen sacks of cotton from Aleppo. Between 1391 and 1394 three ships sailed to Famagusta, the port of Cyprus, with cargoes of French, Flemish, Spanish, and Florentine cloth, French linen, as well as iron, tin, and coral. In exchange they traded spices, pepper, and sugar, furthermore cotton and Oriental fabrics, such as bocasin (a species of fine buckram), camlet, camoca, and gold brocade, as well as gold thread and jewels. The captains were commissioned to procure as large a quantity of spices as possible and then cotton, which was a less valuable commodity.

In the fourteenth century the great Florentine trading house of Bardi sent its agent Pegolotti (see Ciba Review No. 27, page 967) to Cyprus, in order to negotiate a reduction of Armenian export duties from there. The firm of Bardi maintained branches in all the more important centres of European and Eastern trade, and Pegolotti had been in England and in the Low Countries before being sent to the East to represent the interests of his firm. His journey was of considerable importance for the history of the subject under discussion; Pegolotti's journals not only contain a detailed list of all the kinds of cotton known at that time, they also give particulars of the esteem in which the different kinds were held. According to Pegoloud the best cotton was that which came from Epiphania and Aleppo (Hanna and Haleb). All who visited those cities declared that they were surrounded by fields which yielded extremely rich harvests. Second place was taken by the cotton of Lesser Armenia, concentrated round the towns of Korykos (Burcho) and Adana, and by that which came from the region of Damascus. Third in rank came the cotton grown on the Syrian coast and on the island of Cyprus. The fact that Cyprian cotton was held in good repute in Europe was due to the importance of the island as a transit port rather than to the quality of the cotton grown there. European cotton was apparently regarded as inferior to that of the Levant, the best came from Apulia, then followed Calabrian and Maltese cotton, whilst Sicily produced the poorest quality.

At the beginning of the fifteenth century Venice concluded trade agreements with Egypt, where the Sultan Borsban sought to concentrate all foreign trade in his own hands. Though he was successful in monopolizing the trade in sugar and pepper, the Venetian merchants resisted the application of the same measures to cotton by having the bales brought to their ships, where they made their purchases without ever going on shore. By this time the ports of southern Syria had almost entirely lost their former importance. In the fifteenth century travellers reported that in Acre, the foremost commercial town of the states founded by the crusaders, only a few houses and vaults remained, where the Venetians stored the cotton which they purchased in the interior. In New Acre, which was about two miles distant, a factory or trading post was established exclusively for the cotton trade. As shipping was confined almost entirely to the transport of this one commodity, traffic was so slight that the two or three Saracens who guarded the port signalled the arrival of the ships from the old town to the new. The boats bringing pilgrims frequently took back cargoes Of cotton with them.

The rise of the fustian industry in South Germany and Switzerland increased the demand for cotton to such an extent that Venice was hard put to it to cope with the volume of trade which developed. All the important centres, Constance, Ulm, Biberach, and Augsburg, procured their raw materials through Venice. The turnover of the Venetian cotton trade in the early fifteenth century amounted to 250,000 ducats annually. It was for the most part Syrian and Cyprian cotton, though a small quantity of the Egyptian kind was also imported; by reason of the fineness, length, and durability of the fibre Egyptian cotton was very much prized. In 1465 the municipal authorities of Ulm issued a decree stipulating that no weaver might buy cotton from a person who had not brought the goods over the Alps from Venice himself, or had them brought over in his name. Detailed regulations governed transport fees and duties payable on the goods, which were brought from Venice on mule-back, the distance being covered within ten days or a fortnight. When the commercial blockade of Syria was removed in 1500, a whole fleet sailed for Beirut for the sole purpose of procuring cotton, for which the merchants of Central Europe were prepared to pay any price. Cotton was scarce enough at the best of times, and the constant wars had made it almost unprocurable. The discovery of America and of the sea route to India did not at first make any difference to this trade. In 1570 the cotton merchants of Ulm were forbidden to unload, exhibit, or process Brazilian cotton in the city. In the following year, however, there was such a scarcity of Cyprian cotton that the municipal authorities were obliged to permit the sale of Brazilian and Syrian cotton (from Tyre). The Swiss cotton industry also suffered as a result of this scarcity of raw material. A Zurich cotton merchant who went to Venice in 1584 in order to buy raw material, was obliged to report that he had been unable to procure any. He added that two ships with a cargo of several thousand sacks were expected any day, so that cheap cotton would then be procurable. He suggested buying a large quantity with public funds, and having it transported to Zurich. The city corporation considered the matter, but decided that it would not be advisable to take the purchase of cotton out of private hands. That was the time when the old cotton trade was nearing its end; the second period was approaching, in which the importance of raw materials from the East declined rapidly and the imports of semi-finished products from India created a new industry in Europe.

Fustian Weaving in South Germany from the Fourteenth to the Sixteenth Century

By H. Wescher

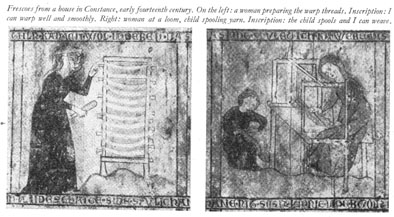

Fustian first appeared in Germany at a very early date. It is mentioned in 1318 in the statutes of the grocers of Brieg, and as a record dating from the end of the century has been preserved which states that the weavers of Schweidnitz in Silesia made "Parchan" (Barchent = fustian), it may be assumed that the Silesian textile centres produced cotton as well as linen goods, though it is improbable that the former were of any great importance. In South Germany, where fustian weaving became an industry of the first rank during the fourteenth century, the manufacturer was probably preceded by the merchant, and it is to be assumed that the trade in fustians was on a large scale. This assumption supports the belief that cotton was introduced into Germany via Constance. Constance played an outstanding part in the history of medieval commerce. Its merchants, who were organized in one of the oldest guilds, frequented the Fairs of Champagne, and maintained trade relations with Lombardy, where textiles of Constance were already being sold in the thirteenth century. The years between 1350 and 1460 were the most prosperous period for medieval Constance. The ships of her merchants sailed the seven seas; Constance was linked commercially with Spain and Flanders, with Geneva and Avignon, no less than with the cities of the German Fairs. "Tela di Constanza" (linen of Constance) was the most famous and most important article exported from the city, and special regulations governing its export were issued in 1283; fustians were, however, also stored in the warehouses of Constance.

Mention of public examinations of fustians is made as early as 1375, and from the following year on, three fustian inspectors were added to the linen inspectors already officiating in the City Hall. This development shows that the fustian trade must have attained considerable importance. It appears that fustian weaving was at first carried on by the linen weavers without question from any side. In 1409 the wool-weavers protested against this state of affairs on the grounds that the linen-weavers had broken the guild laws by using the bow for beating cotton, that instrument being reserved for the wool-weavers. The town magistrates settled this dispute in favour of the linen-weavers on condition that the use of the bow was strictly confined to preparing cotton. This report shows that fustian-weaving in Constance was no more than a side-line of the linen-weavers.

In other towns, particularly Ulm in southern Germany, it very soon assumed much greater dimensions. In Ulm, too, the weaving trade had a long tradition. Documents of the period between 1292 and 1296 mention a "textor", a "panifex", and a "panicisor", a weaver, a cloth-maker, and a cloth-merchant. The clothmaker's guild achieved great importance, and was not long in extending its influence to the sphere of politics. The arms of the guild a red lion rampant with gold crown and collar adorn the city wall. The cloth-workers' guild originally comprised both weavers and dealers, but the two groups separated in the course of the fourteenth century. Whilst the dealers gradually developed into great merchants, who sold woollen cloth all over Europe, and who later took up the fustian trade, the goods which they sold continued to be provided by two separate groups of weavers, the urban woolweavers and the rural linen-weavers. In the fourteenth century the two groups quarreled over the right to weave fustians, a dispute in which the linen-weavers appear to have gained their point.

In other towns, particularly Ulm in southern Germany, it very soon assumed much greater dimensions. In Ulm, too, the weaving trade had a long tradition. Documents of the period between 1292 and 1296 mention a "textor", a "panifex", and a "panicisor", a weaver, a cloth-maker, and a cloth-merchant. The clothmaker's guild achieved great importance, and was not long in extending its influence to the sphere of politics. The arms of the guild a red lion rampant with gold crown and collar adorn the city wall. The cloth-workers' guild originally comprised both weavers and dealers, but the two groups separated in the course of the fourteenth century. Whilst the dealers gradually developed into great merchants, who sold woollen cloth all over Europe, and who later took up the fustian trade, the goods which they sold continued to be provided by two separate groups of weavers, the urban woolweavers and the rural linen-weavers. In the fourteenth century the two groups quarreled over the right to weave fustians, a dispute in which the linen-weavers appear to have gained their point.

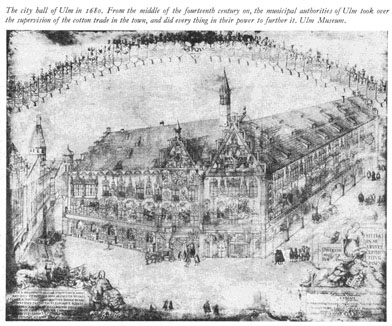

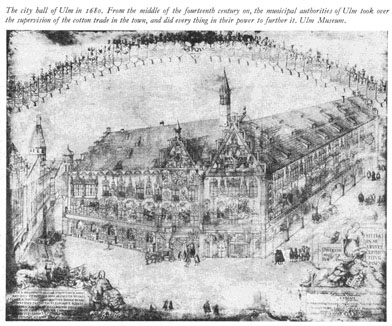

According to the chronicles cotton first appeared in Ulm in about 1320. It is assumed that fustian-weaving came to Ulm from Constance. This assumption is based on the fact that the first exhibition of fustians was held in the precincts of the monastery of the Benedictines at Ulm, who belonged to that congregation of the order which had its centre at Reichenau near Constance. Cotton-weaving was at first doubtless a domestic industry of the rural districts; such industries were often dependent on the monasteries to take over their products. In Ulm, however, the city corporation undertook the supervision of the cotton-weaving trade in the middle of the fourteenth century. In doing so the corporation adopted a policy which ran counter to the customs and interests of the guilds in so far as support was given to craftsmen who did not belong to the town. By forestalling the claim of the guilds to a monopoly of this trade, the merchants, who controlled both the imports of raw materials and the sale of the finished goods, had unlimited labour at their disposal, particularly after Biberach and Memmingen had issued a decree against weaving in the country districts. The trade remained concentrated in the town of Ulm, where the official inspection of fustians was a necessary preliminary to all sales. The city council secured the prohibition of any similar inspection within an area of three leagues from the gates. They safeguarded the quality of the goods so consistently that the fustians of Ulm came to be recognized internationally as standards of excellence. During the most flourishing period the cotton goods of Ulm not only dominated the South German markets, they were also exported to Switzerland and Italy as well as to Lubeck, Antwerp, and Calais. Their fame spread even farther; the chronicle of Ulm relates that when an Andalusian knight named Petro Tafor arrived at Ulm, he expressed his pleasure at being able to visit the place of origin of fabrics with which he had been familiar in his native country.

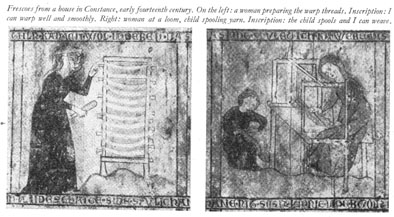

The various trade regulations of the fifteenth century contain such detailed directions that we are able to form a fairly good impression of the nature and extent of the cotton industry. In all fustians the weft had to be of cotton and the warp of linen. The warp-threads consisted entirely of flax fibre, the use of hemp being strictly forbidden. Even the kind of flax which was to be used was laid down in the regulations; flax from Riga, which was transported via Leipzig and Nuremberg, was banned as being of inferior quality to that grown in South Germany. The processing of the raw cotton began with beating the fibre in order to loosen it after having been compressed in the bales during the long period of transport. During this process the cotton was spread out on a wicker or wire frame; when it was beaten, dirt, sand, etc. fell through the gaps of the frame. Then the carders' turn came, it was their task to disentangle the fibres and in some cases to comb them. Carding was originally a part of the weaver's work, but in more recent records of the trade the carders are listed separately.

The various trade regulations of the fifteenth century contain such detailed directions that we are able to form a fairly good impression of the nature and extent of the cotton industry. In all fustians the weft had to be of cotton and the warp of linen. The warp-threads consisted entirely of flax fibre, the use of hemp being strictly forbidden. Even the kind of flax which was to be used was laid down in the regulations; flax from Riga, which was transported via Leipzig and Nuremberg, was banned as being of inferior quality to that grown in South Germany. The processing of the raw cotton began with beating the fibre in order to loosen it after having been compressed in the bales during the long period of transport. During this process the cotton was spread out on a wicker or wire frame; when it was beaten, dirt, sand, etc. fell through the gaps of the frame. Then the carders' turn came, it was their task to disentangle the fibres and in some cases to comb them. Carding was originally a part of the weaver's work, but in more recent records of the trade the carders are listed separately.

The spinner was not only responsible for the thread which he spun, but also for the waste material which was left over. This waste-fibre was used as a material for raincapes of cotton cloth which was felted by means of vigorous fulling. These capes were lengths of cloth with a hole cut in the middle through which the head was passed. The two ends hung down back and front. Precautions to safeguard the purity of the woven goods of Ulm were carried to such extremes that it was forbidden to give cotton to spinners who had previously spun wool of Biberach or Weissenhorn, two towns in the vicinity of Ulm. After the thread had been boiled in the approved manner with wood and ashes-the use of lime and woadashes was prohibited-it was handed over to the weaver who had prepared the warp of linen threads. While the fabric was on the loom, the weaver was allowed to pumice it once. For this purpose only hard stones were permitted, not cretaceous stone. Only a certain specified number of finished cloths were allowed to be pumiced, in order to give them additional lustre.

It was strictly forbidden to wet the finished fabrics in the cellar. The last stage of the process was entrusted to the shearer, who roughened the fustian, and sometimes applied the dressing as well. The regulations prescribed a dressing consisting of pure white of egg. Dyes had to be of "resin or burnt in the sack", or made according to some other approved method.

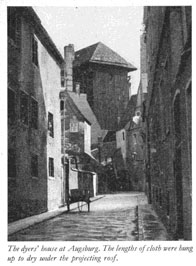

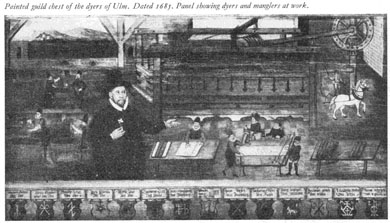

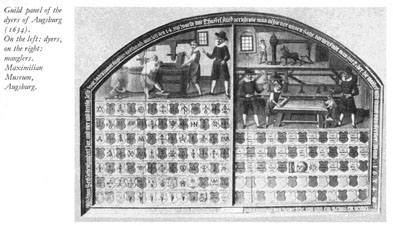

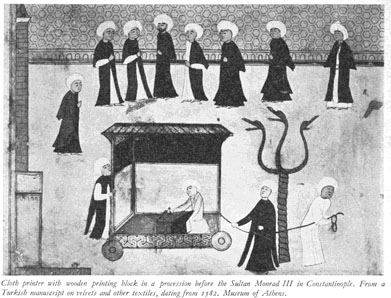

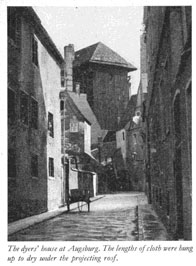

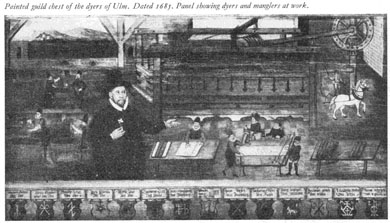

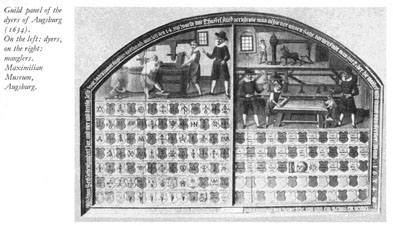

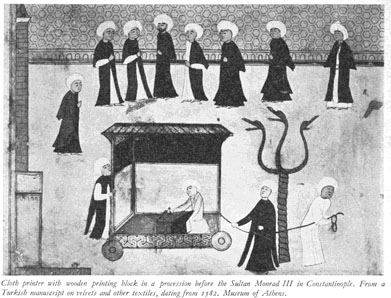

Dyeing, like glazing, painting, and printing, was only permitted where the inferior fustians were concerned. These were the fabrics which had received "the dye certificate" after three superior qualities had been selected and set apart. Dyeing became important in Ulm during the seventeenth century; at the time when the cotton industry was at its height it was comparatively insignificant, being confined to red and black dyeing on a small scale. The merchants of Ulm preferred to send their goods to Augsburg to he dyed; only the most inferior kinds of cloth were entrusted to the local dyers, who were instructed to dye according to Augsburg methods. Nevertheless, the smaller Swabian towns, particularly Biberach, where the manufacturers were concerned with quantity rather than quality, sent their textiles to Ulm to be dyed. The motive which underlay this practice was the desire to have the Ulm mark on the cloths which were dyed there. This was done so frequently that the Biberach dyers complained of the way in which they were neglected.

Dyeing, like glazing, painting, and printing, was only permitted where the inferior fustians were concerned. These were the fabrics which had received "the dye certificate" after three superior qualities had been selected and set apart. Dyeing became important in Ulm during the seventeenth century; at the time when the cotton industry was at its height it was comparatively insignificant, being confined to red and black dyeing on a small scale. The merchants of Ulm preferred to send their goods to Augsburg to he dyed; only the most inferior kinds of cloth were entrusted to the local dyers, who were instructed to dye according to Augsburg methods. Nevertheless, the smaller Swabian towns, particularly Biberach, where the manufacturers were concerned with quantity rather than quality, sent their textiles to Ulm to be dyed. The motive which underlay this practice was the desire to have the Ulm mark on the cloths which were dyed there. This was done so frequently that the Biberach dyers complained of the way in which they were neglected.

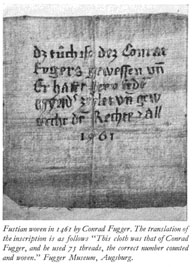

The great majority of Ulm fustians were not dyed, but merely bleached. The whiteness of these textiles was one of their most outstanding features; this was stated explicitly by the Venetian ambassador in 1492. The whole process of bleaching was under strict supervision. Care was taken to ensure that the bleachers had suitable premises and equipment, that they prepared the bleaching bed with wood ashes and not with burnt clay. The bleachers were instructed to examine the cloth on the bleaching ground every day, but not to turn it more than once a week. Bleaching took place between Ash Wednesday and the feast of St. James. During these months the cloth often changed hands several times. Nobles and artisans, trustees of charitable foundations as well as aldermen of the town, all took part in the speculation which consisted in buying the unbleached cloth at a low price and selling it at a profit. Of the seven municipal bleaching grounds five were used exclusively for fustian bleaching, and the quantity of cloth bleached there far exceeded the total production of Ulm. Every year about 60,000 lengths of bleached fustian were exhibited at the cloth hall, whilst the quantity woven in Ulm varied between 9000 and 10,000 lengths. When the weavers presented their cloth to be tested on St. James' Day, it was carefully examined by the appointed officials, and the fabrics which were passed received a stamp. The examination consisted chiefly in counting the threads, which numbered 1170 in ordinary fustian and 1300 in the finer kinds. According to their quality the cloths were stamped with the image of an ox, a lion, or a bunch of grapes. The confidence in these marks was so great that bales of Ulm cloth often changed hands eight or ten times without being opened. The price of one fardel of fustian was about 86 fl. in the fifteenth century; in the course of the following century it increased to 115 and 120 fl.

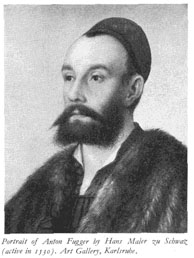

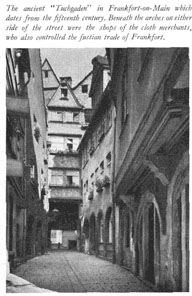

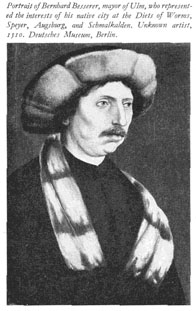

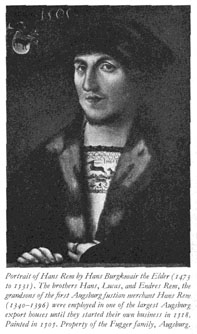

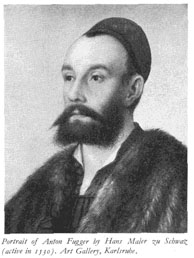

Sales were in the hands of a few influential merchants working together with businesshouses in other cities such as Basle, Frankfort, Nuremberg, Reutlingen, Ratisbon, etc. The trade was closely linked with the names of a few influential families, foremost among whom were the Ehingers and Besserers. The house of Ehinger sent fustians and linen as well as furs and wine down the Danube to Bavaria, Austria, Hungary, and even to Turkey; in exchange for these goods they imported steel, iron, salt, and hides. Of even greater importance were the Besserer family; they were partners in some of the most important South German trading companies, and thus exerted considerable influence far beyond the precincts of Ulm. In the middle of the fifteenth century Hans Besserer was a member of the powerful Ravensburg company, and Wilhelm, another member of the family, maintained relations with a company founded by the Vehlins of Memmingen and by Lukas Welser of Augsburg. This link with the most influential Augsburg firm was instrumental in securing permission for Antonius Welser at the beginning of the sixteenth century to export his goods to Ulm and to trade goods of Ulm in exchange for them. During the Diet of Constance in 1507 Jörg Besserer led a joint action of the towns, in which representations were to be made to the Emperor against the excessive burden of taxes and other dues which were threatening to cripple trade and industry.

Sales were in the hands of a few influential merchants working together with businesshouses in other cities such as Basle, Frankfort, Nuremberg, Reutlingen, Ratisbon, etc. The trade was closely linked with the names of a few influential families, foremost among whom were the Ehingers and Besserers. The house of Ehinger sent fustians and linen as well as furs and wine down the Danube to Bavaria, Austria, Hungary, and even to Turkey; in exchange for these goods they imported steel, iron, salt, and hides. Of even greater importance were the Besserer family; they were partners in some of the most important South German trading companies, and thus exerted considerable influence far beyond the precincts of Ulm. In the middle of the fifteenth century Hans Besserer was a member of the powerful Ravensburg company, and Wilhelm, another member of the family, maintained relations with a company founded by the Vehlins of Memmingen and by Lukas Welser of Augsburg. This link with the most influential Augsburg firm was instrumental in securing permission for Antonius Welser at the beginning of the sixteenth century to export his goods to Ulm and to trade goods of Ulm in exchange for them. During the Diet of Constance in 1507 Jörg Besserer led a joint action of the towns, in which representations were to be made to the Emperor against the excessive burden of taxes and other dues which were threatening to cripple trade and industry.

About this time difficulties in the fustian industry became evident, difficulties against which the merchants had striven with varying success throughout the fifteenth century. The expansion of the industry over the whole of Swabia, with weaving centres at Ravensburg, Memmingen, Biberach, and Urach, of necessity made the problem of marketing the goods which were produced a very grave one indeed. The regulations governing the inspection of fustians which were issued in 1419 had been drawn up as a means of overcoming the difficulties in disposing of the goods, and shortly after that time distress became acute. The weavers were entirely in the hands of the cloth merchants, who held a monopoly of the cotton trade; they were frequently obliged to pledge the finished goods to the merchants when they bought the raw material from them. The increasing difficulties of the trade were reflected by bitter feuds between the weavers of the towns and those of the rural districts. In 1457 the weavers' guilds were successful in bringing about an increase of the fee which the country weavers had to pay for the examination of their products by the official inspectors; they also managed to have a regulation passed which limited the number of looms to be maintained by a country weaver to two. When in 1503 the country towns of Swabia suggested an arrangement which was to fix the number of country weavers at a maximum of 420 with two looms each, the guilds brought their protest against this regulation before the Emperor, without success, however, as he upheld the arrangement of the country weavers. Finally the constant wars brought about a decline in the trade which could not be made up again.